Stainless steel is utilized in various industries and is most sought-after in forging applications. Alloy forgings are designed to be extremely durable and resistant to corrosion and heat. Thus, stainless steel’s best properties — corrosion resistance and strength — are leveraged and magnified by forging.

As the demand for stainless steel grows, the number of companies offering stainless steel forging services is bound to increase. However, this high-precision process requires a high level of manufacturing expertise and experience. Hence, you must consider several factors when choosing the best forging manufacturer.

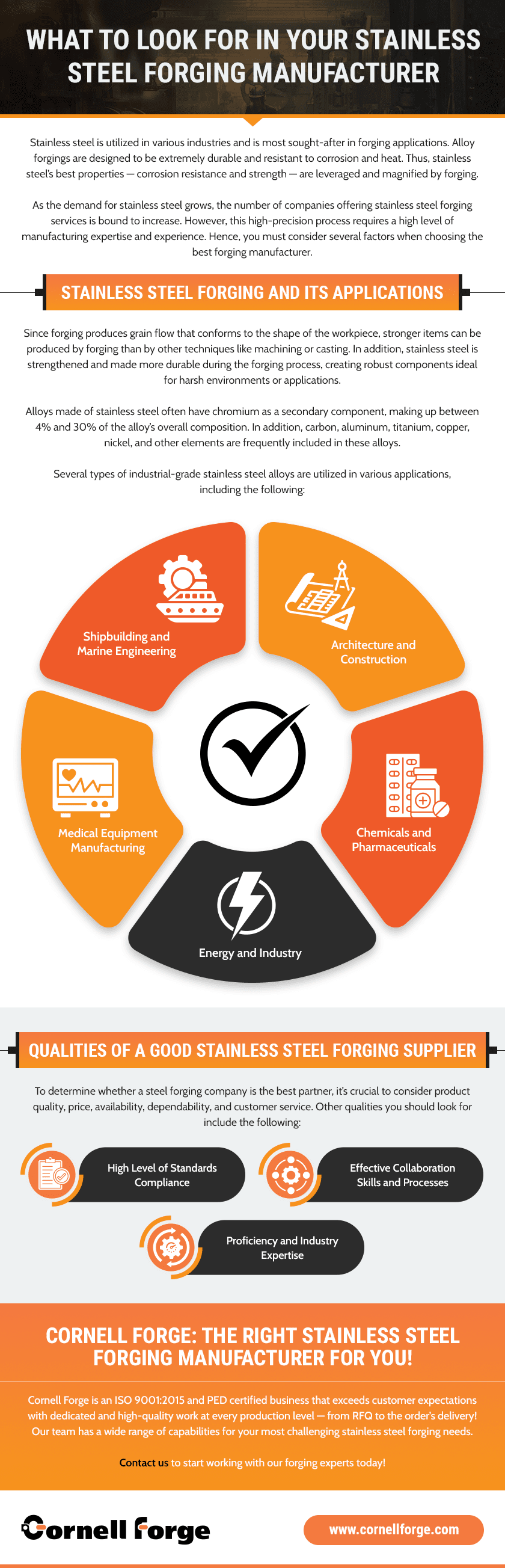

Stainless Steel Forging and Its Applications

Since forging produces grain flow that conforms to the shape of the workpiece, stronger items can be produced by forging than by other techniques like machining or casting. In addition, stainless steel is strengthened and made more durable during the forging process, creating robust components ideal for harsh environments or applications.

Alloys made of stainless steel often have chromium as a secondary component, making up between 4% and 30% of the alloy’s overall composition. In addition, carbon, aluminum, titanium, copper, nickel, and other elements are frequently included in these alloys.

Several types of industrial-grade stainless steel alloys are utilized in various applications, including the following:

- Architecture and construction

- Chemicals and pharmaceuticals

- Energy and industry

- Medical equipment manufacturing

- Shipbuilding and marine engineering

Qualities of a Good Stainless Steel Forging Supplier

To determine whether a steel forging company is the best partner, it’s crucial to consider product quality, price, availability, dependability, and customer service. Other qualities you should look for include the following:

High Level of Standards Compliance

A reliable steel forging supplier can deliver custom services compliant with industry standards. They must offer competitive prices while delivering unmatched, high-quality, and undamaged products on time. Working with someone capable of doing all these helps increase your manufacturing ROI and streamline your operations.

Effective Collaboration Skills and Processes

Constant and clear communication with a forging company saves you time, minimizes errors, and allows adjustments in areas and circumstances that require it. It also ensures that you receive your orders on time and with the highest quality, avoiding delays in your production. A forging provider that respects your time restrictions and deadlines can also save you a lot of money in the long run.

Proficiency and Industry Expertise

The ideal steel forging provider can serve as a resource for information and advice. For instance, they can assist clients in evaluating new production techniques, such as switching from casting to forging, where applicable. When relationships are built and nurtured to this level, you are guaranteed consistent, reliable, and high-quality components every time.

Cornell Forge: The Right Stainless Steel Forging Manufacturer for You!

Cornell Forge is an ISO 9001:2015 and PED certified business that exceeds customer expectations with dedicated and high-quality work at every production level — from RFQ to the order’s delivery! Our team has a wide range of capabilities for your most challenging stainless steel forging needs.

Contact us to start working with our forging experts today!