Forging, the process of shaping cold, warm, or hot metal by striking it with a hammer or die, is a highly skilled manufacturing operation. If your company lacks in-house forging skills or experience for a product, you might be considering offshore outsourcing to meet your needs.

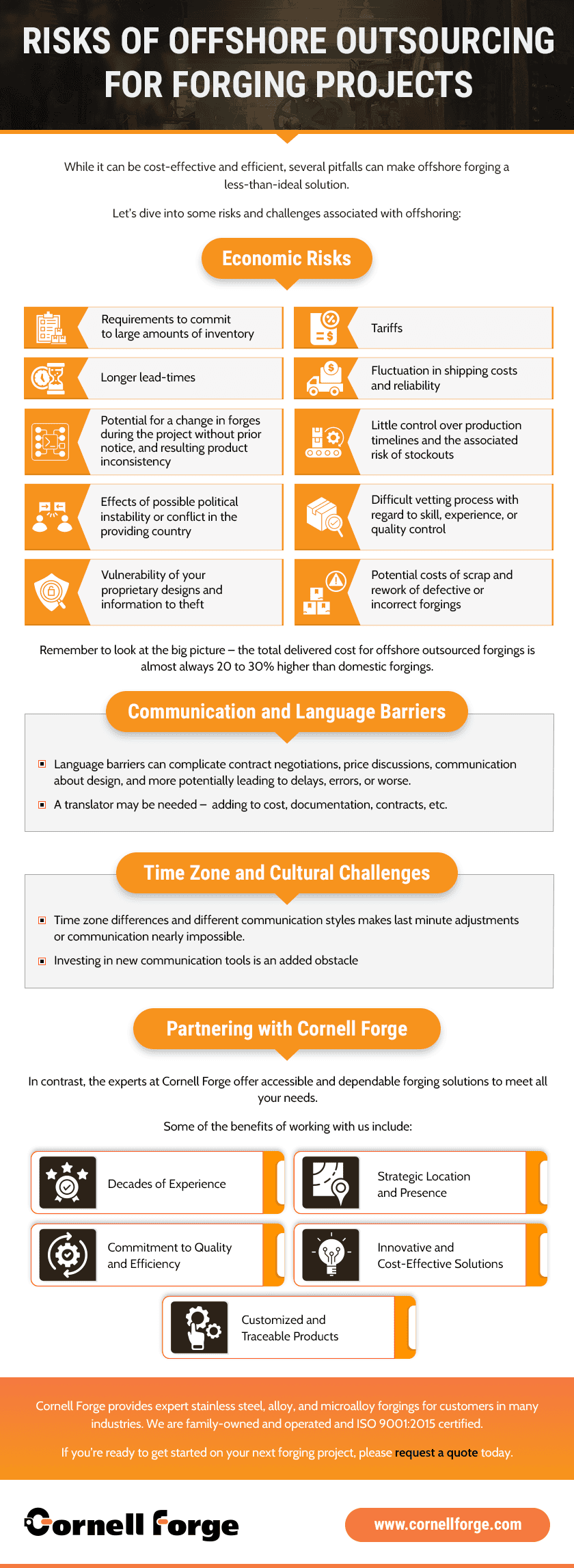

While it can be cost-effective and efficient, several pitfalls can make offshore forging a less-than-ideal solution. Here, we’ll look at some of the economic risks and business challenges that may arise when outsourcing production to a third-party manufacturer overseas.

Economic Risks of Offshore Forging

It is no small task to operate a forge and manage a team of skilled metalsmiths in-house if it is not your company’s specialty. For that reason, forgings are often obtained by partnering with a contract manufacturer.

When manufacturers elect to work with a company outside the US for forgings, their focus is usually on saving manufacturing costs in an effort to boost profits. Commonly cited benefits include access to inexpensive labor and better raw material prices due to geographical proximity. These make offshore outsourcing seem like a great plan; however, more often the economic and business risks outweigh any cost savings (and frequently those savings are negligible anyway).

Economic risks to consider include:

- Requirements to commit to large amounts of inventory

- Longer lead-times

- Potential for a change in forges during the project without prior notice, and resulting product inconsistency

- Effects of possible political instability or conflict in the providing country

- Vulnerability of your proprietary designs and information to theft

- Tariffs

- Fluctuation in shipping costs and reliability

- Little control over production timelines and the associated risk of stockouts

- Difficult vetting process with regard to skill, experience, or quality control

- Potential costs of scrap and rework of defective or incorrect forgings

Remember to look at the big picture – the total delivered cost for offshore outsourced forgings is almost always 20 to 30% higher than domestic forgings.

Communication and Language Barriers in Offshore Forging

Another risk involved with offshore forging is communication. Despite best efforts, language barriers can and do make it more challenging to negotiate contracts and pricing. It can also be more challenging to discuss design details, production requirements, quality expectations, and timelines effectively. Miscommunication in these areas can result in delays, product errors, or wasted material.

To facilitate effective communication, it may be necessary to work with a translator, which adds to your costs. Translation services will likely be required for documentation and contracts in addition to conversations and meetings.

Time Zone and Cultural Challenges in Offshore Forging

Working across multiple time zones complicates efficient communication if there are last-minute adjustments to production or quality control issues. Cultural differences may also present challenges. This can include differences in communication styles as well as how questions are posed and responded to. The ways in which work schedules and holidays align (or don’t) may create gaps in communication or production as well.

To ensure effective collaboration, you may need to invest time and money in new digital communication tools or be willing to schedule meetings and take calls at different times of the day.

Advantages of Partnering With Cornell Forge

Any of the pitfalls above can result in overspending, poor quality forgings or defective finished products, delays in time to market, or even damage to your company’s reputation. These are probably not risks your company is willing to take.

In contrast, the experts at Cornell Forge offer accessible and dependable forging solutions to meet all your needs.

Some of the benefits of working with us include:

- Decades of Experience: We have over 90 years of experience. We produce complex and challenging parts, provide design support, and focus on continuous improvement.

- Strategic Location and Presence: Our Chicago facility is ideally located for fast access to raw materials and additional manufacturing services, like machining and heat treating, as needed.

- Commitment to Quality and Efficiency: We are dedicated to quality and process optimization, which means you get consistently well-made products, reliable on-time delivery, shorter lead times, and responsive customer service.

- Innovative and Cost-Effective Solutions: In many cases, our net and near-net forging capabilities mean additional machining or manufacturing processes are not necessary. Our pricing is internationally competitive without compromising on product or service quality.

- Customized and Traceable Products: All of our tooling is custom-built in-house to meet your project’s requirements. Materials and parts are carefully tracked to ensure excellent traceability.

Connect With Cornell Forge for Superior Forging Solutions

Cornell Forge provides expert stainless steel, alloy, and microalloy forgings for customers in many industries. We are family-owned and operated and ISO 9001:2015 certified.

If you’re ready to get started on your next forging project, please request a quote today.