Forging isn’t just in our name...

It’s how we

made our name

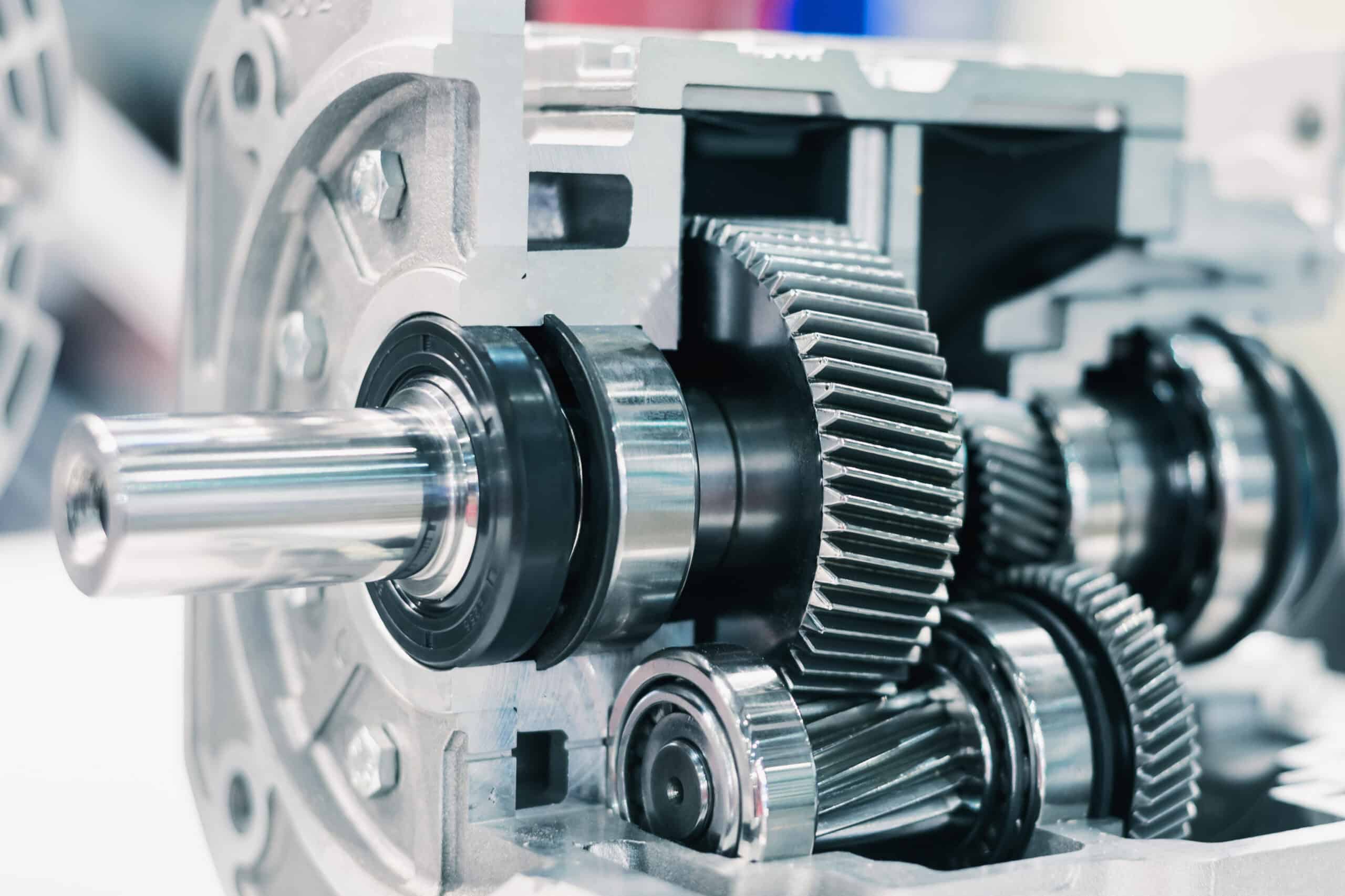

Precision Metal Forging Solutions: Trusted Craftsmanship for Industrial Applications

At Cornell Forge Co., we provide reliable, high-quality metal forging solutions across the United States. As a trusted metal forge company, we specialize in creating durable, precision-crafted components for a wide range of industrial applications. Our team is dedicated to delivering products that meet the highest standards of performance and reliability.

The Highest Quality

Forged Products Made in the USA

Cornell Forge is an ISO 9001:2015 certified company and maintains strict process controls to achieve our consistent quality.

What Makes Our Forge Company Stand Out?

Our industrial forge operations combine decades of expertise with advanced machinery to manufacture heavy-duty forging solutions. We are recognized among the top American forging companies in the USA for our accuracy and attention to detail. From metal forging parts and components to custom-designed solutions, our experienced engineers guarantee every project meets client specifications. Additionally, our forging factory maintains rigorous quality control to deliver consistent, high-quality results.

A Selection Of Industries We Serve

Markets Served

Cornell Forge’s current customers are found across a broad range of industries producing a diverse array of products and components to exacting standards.

How Can You Partner With Leading Forging Suppliers?

Working with forging suppliers like Cornell Forge Co. means access to a comprehensive range of services. Our forging group supports clients with custom metal fabrication and forging expertise, making sure solutions fit unique industrial requirements. As one of the leading American forging manufacturers, we supply forged metal parts to suppliers across multiple sectors. Clients can expect timely delivery, competitive pricing, and expert guidance from initial design to final production. Whether you need a top-rated metal forging company for large-scale projects or precision metal forging parts and components, we are your trusted partner for American-made forging excellence.

Contact us today to discuss your project requirements and experience unparalleled craftsmanship from a dedicated forge company serving industries nationwide.

Video

Learn about our customer-first approach, including the benefits our customers enjoy when partnering with us.

Watch our robotic arm in action as it transfers hot platters to a forging trim press.

Learn about forged alloys and their industrial applications.

Learn about key considerations in Closed Die Forging.

Learn about forged parts for agricultural applications.

Understanding the forging process: characteristics, process, applications.

Build to Last

Custom Forgings

For Your Toughest Jobs

Success Stories

Our team has the capability to solve issues for our customers. Here are some examples of some custom solutions we came up with.

FAQ's

At Cornell Forge Co., we are renowned for our precision forging, advanced technology, and strict standards. With decades of knowledge, the company consistently delivers durable, high-performance components, earning trust across multiple industries. Their dedication to on-time delivery and material integrity sets them apart from competitors nationwide.

Cornell Forge provides forging solutions for aerospace, automotive, energy, defense, industrial machinery, and oil and gas industries. Their versatile capabilities support high-demand sectors requiring robust, reliable metal components, guaranteeing consistent performance under rigorous operating conditions. Customized solutions accommodate both standard and specialized industrial applications efficiently.

Our company implements comprehensive quality control measures, including material inspections, process monitoring, and dimensional verification. Advanced metallurgical testing and nondestructive evaluation methods guarantee structural integrity. Every stage of forging, from raw material preparation to finishing, is documented, guaranteeing components meet exact specifications and industry standards.

Evaluate suppliers based on experience, certifications, and production capabilities. Look for firms offering quality control, precision forging, material expertise, and scalability. Reviewing past projects, client references, and technological resources guarantees the supplier can consistently meet your component requirements with reliability and adherence to industry standards.

Domestic suppliers reduce shipping delays, import costs, and communication challenges. They offer faster turnaround, better quality oversight, and compliance with local standards. Working with an American forge offers reliable supply chains, strong responsibility, and immediate access to technical support, which is critical for industries requiring precision and timely delivery.

A reputable forging factory should maintain ISO 9001, AS9100, and NADCAP certifications for quality and aerospace standards. Material traceability, method documentation, and adherence to ASTM or SAE specifications ensure compliance. These certifications demonstrate the company’s commitment to excellence, safety, and consistent production of high-quality forged components.